Strukturas LG

THE LG (LAUNCHING GANTRY)

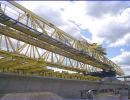

The advanced STRUKTURAS-LG exceeds conventional design limits in modern bridge construction!

The optimized design of the STRUKTURAS-LG leads to an economical, reliable and safe solution for your segmental bridge designs.

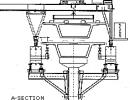

Both the overhead and underslung LG consist of two independent self-supporting main structures combined with advanced lifting equipment, creating an exceptionally flexible system for both the balanced cantilever and the span-by-span method.

Since the launch of the segmental bridge building method in the early 60s, continuous changes in the design criteria have forced new revolutionary solutions to be invented. The implementation of hinged connections between the main parts has made it possible to erect spans with a horizontal radius down to 75m.

Some of our inventions are:

The advanced STRUKTURAS-LG exceeds conventional design limits in modern bridge construction!

The optimized design of the STRUKTURAS-LG leads to an economical, reliable and safe solution for your segmental bridge designs.

Both the overhead and underslung LG consist of two independent self-supporting main structures combined with advanced lifting equipment, creating an exceptionally flexible system for both the balanced cantilever and the span-by-span method.

Since the launch of the segmental bridge building method in the early 60s, continuous changes in the design criteria have forced new revolutionary solutions to be invented. The implementation of hinged connections between the main parts has made it possible to erect spans with a horizontal radius down to 75m.

Some of our inventions are:

- Division of the Main Girder into three sections or more and implemention of a unique hinged connection for both overlane and underlane Gantries have made it possible to erect superstructures with extremely tight curves.

- The hinged connection enables the Main Girder to be kept at one elevation, allowing the Gantry Crane to pick up segments from the superstructure already erected, the current span or even from the next span.

- Our “glue-as-you-go” procedure is a special erection method for wet-joint segmental bridges. A stiff Main Girder allows limited pre-loading of the Gantry, avoiding time-consuming double handling.

Our service extends from complete delivery through partial delivery to consultancy & supervision.

A symmetrical system allows turnaround of the LG without dismantling and reerection. A special gantry crane, able to travel over hinges, combined with a 360-degree horizontal bearing on the bottom block, allows very flexible and smooth segment installation.

Tower elements placed below the support beams allow substantial changes in the longitudinal slope. This facilitates compensation for elevation differences to neighbouring bridges and repositioning of the LG in a vertical direction by “vertical climbing” of the LG.

Easy extension of the support beam for overhead Launching Gantries makes sideways movement of the whole system to the neighbouring bridge or over existing superstructures possible.

Tower elements placed below the support beams allow substantial changes in the longitudinal slope. This facilitates compensation for elevation differences to neighbouring bridges and repositioning of the LG in a vertical direction by “vertical climbing” of the LG.

Easy extension of the support beam for overhead Launching Gantries makes sideways movement of the whole system to the neighbouring bridge or over existing superstructures possible.

For segmental construction where headroom is not a problem then the underslung Launching Gantry can not be beaten for speed and efficiency. Our underslung Launching Gantries can achieve erection cycles from between 1 to 2 days / span.

Independent main structures on each side, only “connected” by the gantry crane, allow transverse adjustment from single to double and even to triple track. Implementation of hinges on our underslung LG has made it possible to erect spans with a horizontal radius down to 70m.

The underslung hydraulic adjustment system permits the whole span to be adjusted in all directions to correct possible misalignments during erection.

Constant ongoing design enhancements and the need for the perfect equipment for different project requirements provide us with a variety of solutions as a basis for handling future challenges.

Our “glue-as-you-go” procedure is a special erection method for wet-joint span-by-span bridges. A stiff main girder allows limited pre-loading of the LG, avoiding time consuming double handling.

More than 25 years of experience in developing bridge building equipment in close co-operation with our customers enable us to supply cost and time saving solutions worldwide.

Independent main structures on each side, only “connected” by the gantry crane, allow transverse adjustment from single to double and even to triple track. Implementation of hinges on our underslung LG has made it possible to erect spans with a horizontal radius down to 70m.

The underslung hydraulic adjustment system permits the whole span to be adjusted in all directions to correct possible misalignments during erection.

Constant ongoing design enhancements and the need for the perfect equipment for different project requirements provide us with a variety of solutions as a basis for handling future challenges.

Our “glue-as-you-go” procedure is a special erection method for wet-joint span-by-span bridges. A stiff main girder allows limited pre-loading of the LG, avoiding time consuming double handling.

More than 25 years of experience in developing bridge building equipment in close co-operation with our customers enable us to supply cost and time saving solutions worldwide.