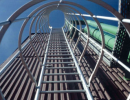

Permanent Ladders

Our fixed ladders (” AlFix”) are made from anodized aluminum profiles. They are modular, based on standardized elements and designed for easy installation and wide application versatility.

They are fully anodized. They feature wide rungs with anti-slip upper side, rounded oblong ladder uprights, seamless upright joining, no sharp edges, round cage uprights fixed in the center of the hoops, optional painting in any desired RAL color.

Construction and materials

• Extruded anodized aluminum profiles;

• Stainless steel fasteners;

• Factory polyester powder coating in any RAL

color on request;

• In compliance with prevailing standards.

Composition

• Standard elements assemble to any desired

length via joint interlocking uprights;

• Uprights: oblong profiles 75 x 25 x 2 mm;

• Rungs are inserted and snapped in the uprights,

and ribbed on the upper side;

• Anti-slip ribs on upper side of the rung.

Dimensions

• Useful rung width: 400 mm (other dimensions

on request);Rungs placed every 11” or 280

mm (other dimensions on request)

Our fixing clamps (patented product) provide for fast and easy installation on most support structures, with or without thermal expansion of the vertical ladder

Fixing clamps

Specially designed fixing clamps (deposited design) are used for the attachment of wall fasteners and safety cage hoops to the ladder uprights. These fixing clamps can be clipped to the ladder uprights at any desired position, which, together with the availability of a large range of wall fasteners, provides for fast and easy installation on most support structures. The ladder can be fitted parallel or perpendicular to the wall. The vertical distance between wall fasteners should not exceed 3 m, except when reinforced uprights are used.

The fixing clamps can be fitted in two ways: completely fixed, or allowing vertical movement. The fitting allowing vertical movement is used for long ladders, to allow for different thermal expansion of the ladder and the building structure.

Technical Specifications

Only materials not subject to corrosion can be used. The ladder is made of aluminum alloy profiles, anodized 10 micron, natural mat finishing; fasteners (bolts, rivets and washers) of stainless steel A2-70 DaN/mm2; joint washers, bushes, plugs, etc. in polyamide and elastomer.

No protective treatment, painting or maintenance is required, except when exposed to aggressive environments.

No welding is allowed. The rungs are clinched into the uprights. Bolts and rivets are used for all other assembly.

The ladder can be polyester powder coated in any RAL color (option).

2. Installation

The ladder is installed vertically.

A single type of fixing clamps is used for the attachments of wall fasteners and safety cage hoops to the ladder uprights. These fixing clamps can be clipped to the ladder uprights at any desired position.

In order to take into account the different thermal expansion of the wall structure and the ladder, the ladder can expand freely within its anchor brackets without deformation or damage.

For lateral access to the ladder, the upper rung will be at approximately 1.5 m above the upper point of access. For access from the top, widened upright projections, allowing a passageway of at least 62 cm, can be used. In the latter case the upper rung is at level with the access floor.

3. Dimensions

The ladder corresponds to standards EN 131 and ISO 14122-4.

The ladder is composed of standardized elements of 3.36 m maximal length, which are assembled to the desired length. These elements are connected by perforated aluminum sleeves that are shifted inside the uprights. Bolts are used for fastening.

The uprights are spaced at 400 mm, the rung axes at 280 mm.

The ladder uprights have an oblong section (75 x 25 x 2 mm) with rounded corners. The rungs are round (Ø 37 mm) with a flattened and grooved anti-slip upper face.

4. Options

The manufacturer can equip the ladder with a safety cage, consisting of hoops and vertical bars. The hoops are bent hollow square profiles of 25 x 25 x 1.5 mm and the vertical bars are hollow round profiles of Ø 18 x 2.5 mm. The safety cage is available with complete hoops, 3/4 hoops or 1/2 hoops. The free passage in the safety cage is +/- Ø 70 cm. The vertical hoop spacing has to be adaptable, but shall not exceed 1 m.

The manufacturer can equip the ladder with rest platforms with safety cage. The ladder is available in multi-flight composition

The lifeline shall be based on a fixed aluminum rail and a stepless safety carriage.

The manufacturer can equip the ladder with a counterbalanced lower sliding ladder to prevent access by unauthorized persons:

• clearance height, i.e. the distance between the floor and the foot of the sliding ladder is maximum 3 m;

• the sliding part is counterbalanced by weights that shift in hollow profiles; axes, springs and cables are of stainless steel, pulley wheels of polyacetal (POM-H);

• release of the sliding part is possible via a mechanism controlled from above, from below or from the side (to be specified). Release via a foot treadle is possible.